Advanced Compact Mbr|Mbbr|Ao|SBR Integrated Wastewater Treatment Process for Textile Dyeing Factory

Basic Info

| Model NO. | MBR-8-10-16 |

| Method | Biological Treatment |

| Usage | Industrial, Home, Agriculture, Hospital, Wastewater Treatment |

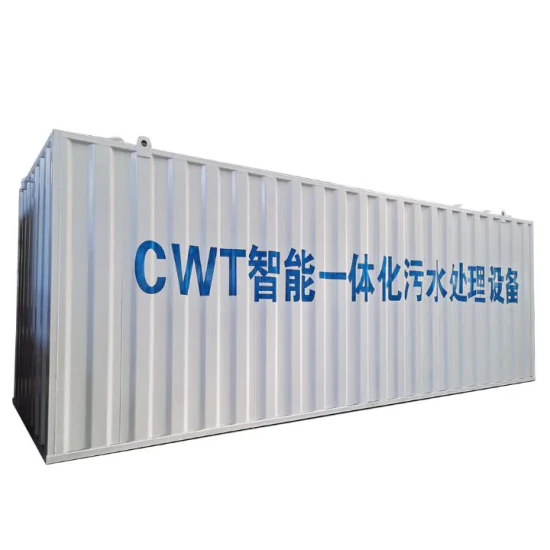

| Name | Wwtp,STP,ETP,Cwt |

| Types | Package,Compact,Small,Mini |

| Applications | Industrial,Municipal,Domestic,Medical,Ship |

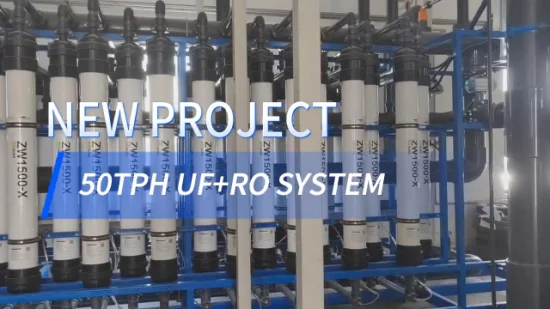

| Craft | Mbr Membrane,Mbbr,Ao,Aao,Disinfect,Filtration |

| Features | Water Clarification,Filtration,Purification |

| Service Life | 30 Years |

| Operation | Automatic |

| Steel Plate Thickness | >8mm |

| Function | Remove Cod BOD |

| Voltage | 220V/ 380V/ Customerized |

| Installation Type | Underground / Onground |

| Colour | Grey/Silver/Blue/Balck/Customerized |

| Use for | Mineral,Printing,Chemical,Dyeing,Starch |

| Material | Carbon Steel,Stain Steel ,FRP,PE,PP |

| Certificate | CE,ISO,BV |

| Transport Package | Wooden Case |

| Specification | SS304 |

| Trademark | Oyang |

| Origin | China |

| HS Code | 8421219990 |

| Production Capacity | 3500 Sets/Year |

Packaging & Delivery

Package size per unit product 250.00cm * 150.00cm * 200.00cm Gross weight per unit product 2000.000kg Lead Time 15 days (1 - 1 Sets)To be negotiated ( > 1 Sets)

Product Description

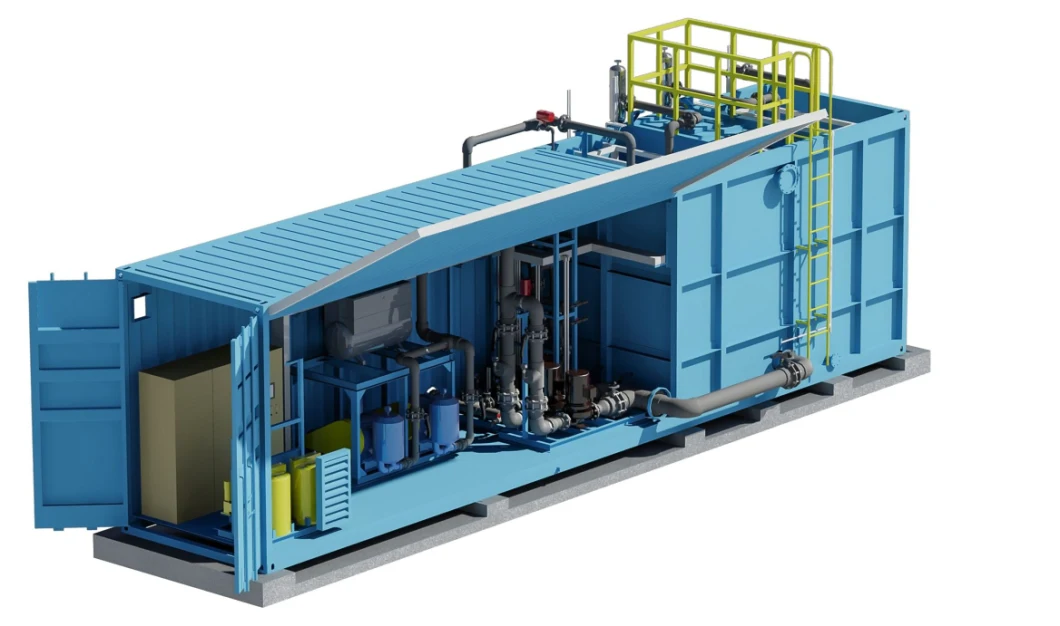

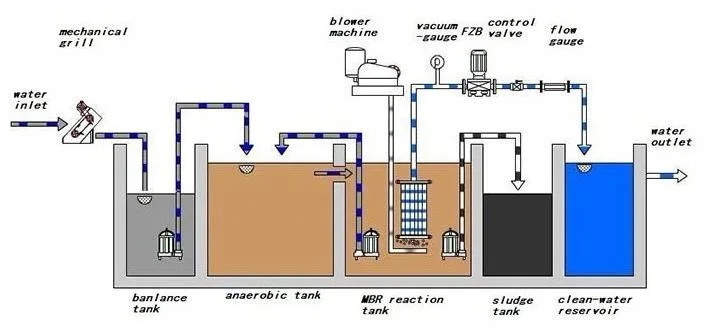

The integrated sewage treatment plant can effectively remove BOD5, COD and NH3-N. It has the characteristics of stable and reliable technical performance, good treatment effect, low investment, automatic operation, and convenient maintenance and operation. At the same time, MBR, MBBR, AO, AAO and other processes can be provided.

Working PrincipleReplacing the end secondary sedimentation tank of traditional biological treatment technology with membrane modules, maintaining a high concentration of activated sludge in the bioreactor, increasing the organic load of biological treatment, thereby reducing the footprint of sewage treatment facilities, and reducing residual sewage by maintaining low sludge load amount of mud. It mainly uses activated sludge and macromolecular organic matter in the retention tank of the membrane separation equipment immersed in the aerobic biological tank. The concentration of activated sludge in the membrane bioreactor system can be increased to 8000~10,000mg/L, or even higher; the sludge age (SRT) can be extended to more than 30 days.

1. A/O biological contact oxidation process is used as the main process, elastic three-dimensional fillers are set in the A-level pool, and three-dimensional columnar elastic fillers are set in the O-level pool, with large specific surface area and high microbial activity, which can quickly remove organic pollutants and have a good denitrification effect. .The specific surface area of the filler is 16-20 times that of the ordinary solid filler, which shortens the biochemical time and greatly reduces the floor space.

2. The equipment can be buried underground: basically does not occupy the surface area, does not need to build a house, heat preservation, and the surface can be greened for driving.

3. Easy to manage and maintain.

4. Small impact on the surrounding environment.

| Model | WSZ1 | WSZ2 | WSZ3 | WSZ5 | WSZ7 | WSZ10 | WSZ15 | WSZ20 | WSZ25 | WSZ30 | WSZ40 | WSZ50 | |

| Capacity | 1 | 2 | 3 | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

| (m3/h) | |||||||||||||

| Number | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 5 | |

| Fan | air volume | 0.31 | 0.59 | 0.67 | 1.02 | 1.72 | 2.5 | 4.11 | 4.11 | 2.5x2 | 2.5x2 | 4.11x2 | 4.11x3 |

| wind pressure | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | |

| power | 0.55 | 0.75 | 1.5 | 1.5 | 2.2 | 3.7 | 5.5 | 5.5 | 3.7x2 | 3.7x2 | 5.5x2 | 5.5x3 | |

| The water pump | traffic | 1 | 2 | 3 | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| lift | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| power | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 3.7 | 5.5 | |

| Area | 6 | 10 | 14 | 19 | 28 | 39 | 58 | 75 | 93 | 113 | 143 | 168 | |

Company Profile

Qingdao Oyang Machinery Equipment is located in Qingdao City,Shandong Province.

Our workshop area is 20,000 square meters and rich experience in sewage treatment.We have long term relationships with makeshift hospital,Sinopec,Railway group,State grid,CRCC,and so on.

The company's main products: integrated sewage treatment equipment, domestic sewage treatment equipment, buried sewage treatment equipment, air flotation machine, industrial sewage treatment equipment, belt filter press, sludge dewatering machine, vacuum filter, rural sewage treatment equipment , Hospital sewage treatment equipment, slaughter sewage treatment equipment, coal mine sewage treatment equipment and other environmental protection equipment.

Products are widely used in domestic industrial and mining enterprises, living quarters, urban and rural areas, food, petrochemical, papermaking, breeding and slaughtering, leather, textile, printing and dyeing, hospitals, hotels and other fields.

Certifications FAQ

1: Are you trading company or manufacturer?

We are manufacturer, specializes in producing waste water treatment plant for more than 10 years.

2.This is my first time to import, i do not know the process, how should i do?

Don't worry about that, we'll help you deal with the whole process.We have different country shipping agent, if you are the first time to import, they will be professional and give you thebest price and deal with everything of transport. They will supply custom clearance and transportation service from thedestination port to your stock.

3.Could you accept the customized ?

Of course, we have professional engineer to design and provide customized severce.

4: Where is your factory located?

Our factory was located in weifang city,and our foreign trade office is in Qingdao city.

5: Do you provide OEM service?

Yes.We provide OEM and ODM service.

6: Do you offer after-sales service?

Yes. Engineers available