Membrane Bioreactor Ethanol Dry Hopping Techniques for Plastic Fermenters

Basic Info

| Model NO. | BLBIO-SJA |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Online Instruction and Commissioning/Spare Parts |

| Feeding Volume | 30%~70% |

| Speed Control | Intelligent Pid Control, 50-1000rpm |

| Ventilation | 1~2vvm |

| Pressure | 0~0.3MPa |

| Transport Package | Wooden Case |

| Specification | 5~300000L |

| Trademark | Bailun Bio |

| Origin | Shanghai |

| HS Code | 8419899090 |

| Production Capacity | 5000 Set/Year |

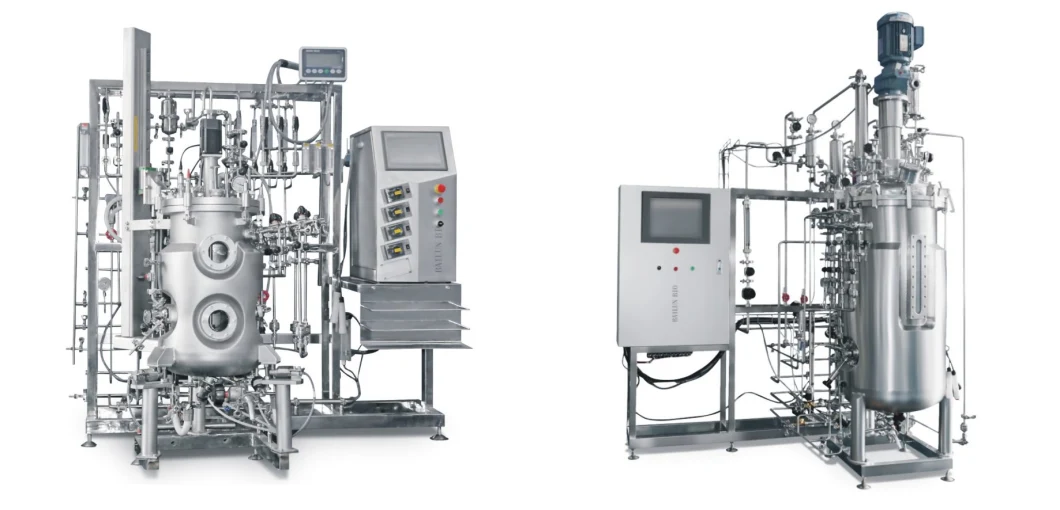

Product Description

Product DescriptionMaterial: 316L stainless steel inside and 304 jacket The diameter and height ratio: 1:2-3Mixing method: magnetic stirring or mechanical stirring one of the two optionalSterilization method: on-site sterilization auto control or manual controlStirring system Mechanical sealing system : high-powered stirring oar, anti-foam oar; AC electrical machine: infinite speed variation; rpm in the fermenter: 50~1000 rpm±1%,The height of the stirring oar can be adjusted

Temperature detection and control Heat by thermostatic water tank and circulate by circulating pump(Denmark), auto control (cooling water+5ºC) to 65ºC±0.1ºC,temperature probe(PT100)pH detection and control 2.00-12.00±0.05 pH, autocontrol by adding acid and base, pH sensor (Mettler/Hamilton, Switzerland) and shielding lead (Mettler/Hamilton, Switzerland). fermenter is auto controlled with peristaltic pumpDO detection and control 0-150±3% displaying precision 0.1%, sensor (Mettler/Hamilton, Switzerland) and shielding lead(Mettler/Hamilton, Switzerland)Feed control Uses peristaltic pump (Spriax, UK) to add materialsAnti-foam control Tested by sensor and added anti foamer by peristaltic pumpIntake control (air) manual control rota meterPressure detection and control Pressure Control: Pressure meter and digital display and digital remote control, pressure controlwe are compliant fermentation equipment for research, development, pilot and production applications.Control system: Siemens PLC, industrial LCD touch computer control, parameters can be set to store,can be remotely connected to the computer through the USB interface, the data

Product range1, Glass fermenter from mini 0.2L to 40L, 2, Stainless steel fermenter for reasearch-pilot-industry like 2L-500L-5000L-500KL. 3, Relative device: Steam generator, Chiller, Air compressor, Tubular centrifuge, Disc centrifuge, Shaker,etc.Fermenter/bioreactor application: 1, Animal vaccine production: Avian influenza vaccine, Porcine PRRS vaccine, Foot-and-mouth disease, Rabies vaccine, Mink vaccine, DTP vaccine, Diphtheria vaccine, Tetanus vaccine, etc.2, Human vaccine production: Diphtheria vaccine, Diphtheria vaccine, Tetanus vaccine, Meningitis vaccine, Pneumonia IV vaccine, Hepatitis B vaccine, etc.3, Culture for microorganism (bacterial,fungi,yeast.etc), mammalian cell, plant cell, algae, enzyme, protein, additives, antibiotics etc.Our Factory:We have three bioreactor fermenter factories in China, one located in Shanghai, two located in Lianyungang city. Welcome to visiting.

Pilot combo stainless steel fermentor,glass fermentor,fermenter, Multiunion fermenter,Multistagefermentation tank, and shaking Incubators, positive join stainless steel fer

mentor.

1. ISO/CE/ASME certificated bioreactor fermenter company. 2. Stable availability, complete specification,easy operation and installation.3. Good after-sales service and quickly reply in 24 hours. 4. Can remote online checking if fermentor have problem during use.5. Can make plant design and 3D drawing.6. Professional, our main engineers have more than 22 years experience of fermentation system.7. Reliable factory, established since 1998.8. Good price good quality with beautiful shape. 9. Can do customize and OEM.10. MOQ 1unit.

Certifications

Packaging & Shipping

Q:Are you factory or trading company?

A:We are a factory

Q:What's the MQQ?

A:1 unit

Q:Do you offer overseas service?

A:Yes,We are dispatch engineer to overseas

Q:Can we visiting your factory?

A:Yes,warmly welcome.Our factory location is Shanghai, China.If want to visit our company , you can fly to Shanghai Pudong Airport

Q:How about your delivery time?

A:1 week to 3 months.Depend on the size and quantity.